About TAS's

BOX BUILD ASSEMBLY

Box-Build Assembly refers to the complete assembly of a customer’s finished product. Assembly of boxes typically includes drilling for conduit fittings, assembly and mounting of terminal blocks, fuses and printed-circuit boards, and termination and installation of connectors for internal wiring systems.

Our Customer Centric Approach

In order to satisfy needs of customers, we are flexible to manufacture single and dual side assemblies as well as mixed technology PCBAs. Our PCB assembly team is managed and run by a team of highly experienced professionals, and we are ready to handle all aspects of manufacturing from small pre-productions to mass production orders.

Why Makes Us Different

Constantly committed to quality and excellence in electronic manufacturing.

We are committed to achieve and improve quality of our processes, products and services.

TAS is also into Box Build Assembly & Contract Manufacturing of Studio Flash Lights since 15 years. The unit is spread across 3000 sq. ft. As per customer specification raw material is procured globally. The product is Assembled, Tested & Quality Checked by experienced engineers. The material is dispatched to customer's warehouse as per their requirements.

Flexibility to handle all customer needs.

We pride ourselves in our flexibility in fulfilling our customers' needs. Our focus on high-mix manufacturing ensures that we are your dependable partner, regardless of your mix/volume requirements.

Techno Advance Systems can be very helpful in the initial design phase of box-build projects by working closely with customers to determine design interconnect layout and component selection.

Specialised turnkey manufacturing.

We are also your total EMS solution: our offering spans from prototyping to end-of-life management.

From terminations to installing circuit boards and the required components, to putting together the housing, Techno Advance Systems is capable of assembling the entire box.

Get In Touch

Fill all information details to consult with us to get sevices from us

FAQ Of Customer

If you have any questions please ask us and we will answer you as quickly as possible Make a question now!

We At Techno Advance Systems, we are constantly pushing the boundaries of what is possible. As a third generation company, we bring decades of experience and expertise to the table. Our deep understanding of our customers' products, as well as the complex and ever-evolving market segments they operate in, allows us to provide a level of service that truly sets us apart.

These parts are where components will sit in the finished PCB. The solder paste itself is a greyish substance consisting of tiny balls of metal, also known as solder. The composition of these tiny metal balls is 96.5% tin, 3% silver and 0.5% copper.

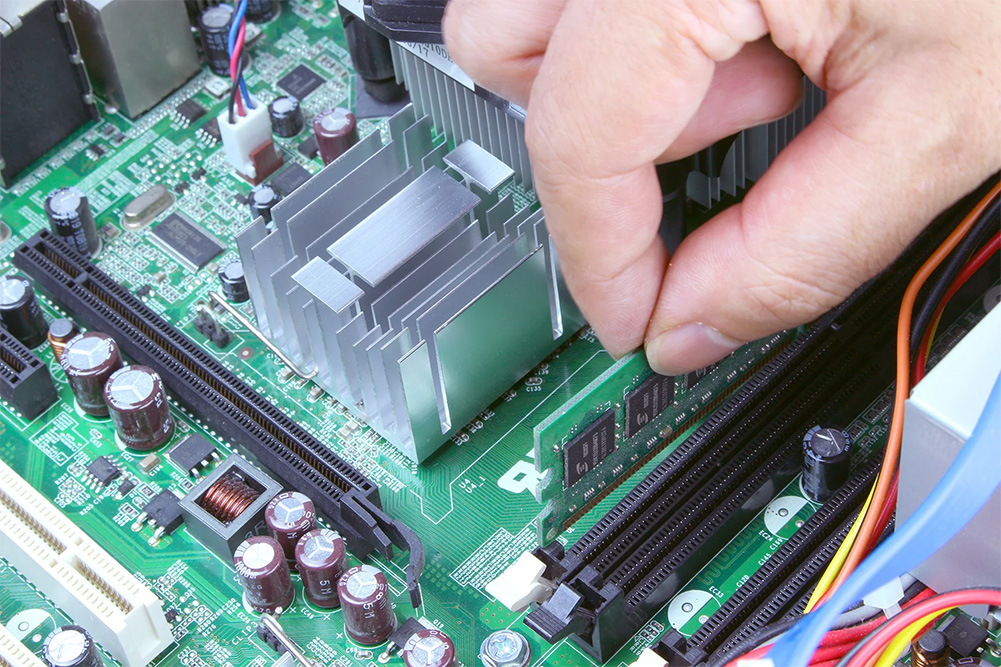

The primary function of a PCB assembly is to integrate the electronic components of a device into a compact or defined space. Acting as the central hub of the electronic circuit of a device, the PCB provides insulation for all other electrical components, allowing them to be safely connected to a power source.

A circuit board assembler prepares printed circuit boards (PCBs) by soldering electronic components onto them. Reading wiring diagrams, following sample boards, selecting electrical components, and finishing the boards with hand tools are all part of this job.

Step 1: Applying Solder Paste Using Stencil.

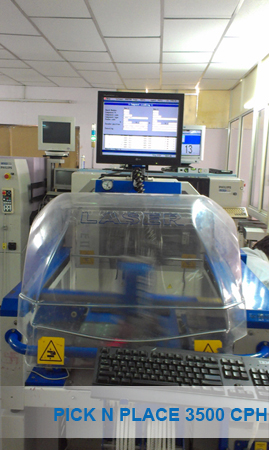

Step 2: Automated Placement of Components.

Step 3: Reflow Soldering.

Step 4: QC and Inspection

Step 5: THT Component Fixation and Soldering.

Step 6: Final Inspection and Functional Test

Step 7: Final Cleaning, Finishing and Shipment.

Step 2: Automated Placement of Components.

Step 3: Reflow Soldering.

Step 4: QC and Inspection

Step 5: THT Component Fixation and Soldering.

Step 6: Final Inspection and Functional Test

Step 7: Final Cleaning, Finishing and Shipment.

Our Approach Towards Quality

We pride ourselves in our flexibility in fulfilling our customers’ needs. Our focus on high-mix manufacturing ensures that we are your dependable partner, regardless of your mix/volume requirements. We are also your total EMS solution: our offering spans from prototyping to end-of-life management.

Techno Advance Systems quality commitment is straightforward: continuous improvement in our day-to-day operation. We believe this will lead outstanding performance and prominent value to our customers. This philosophy is practiced throughout our company, from our operators on the manufacturing floor to our executive management in the office.

We are committed to achieve and improve quality of our processes, products and services by measuring, revising and continuously improving the effectiveness of our quality system, contributing to the productivity.

At TAS, we ensure that our Quality Policy is always appropriate to our purpose: to ensure that nothing short of the best is delivered to our customers. Through our core quality values of teamwork, innovation and continuous improvement, we are able to constantly conceptualize, implement and upgrade our quality systems and plans to ensure that quality is never just an afterthought.